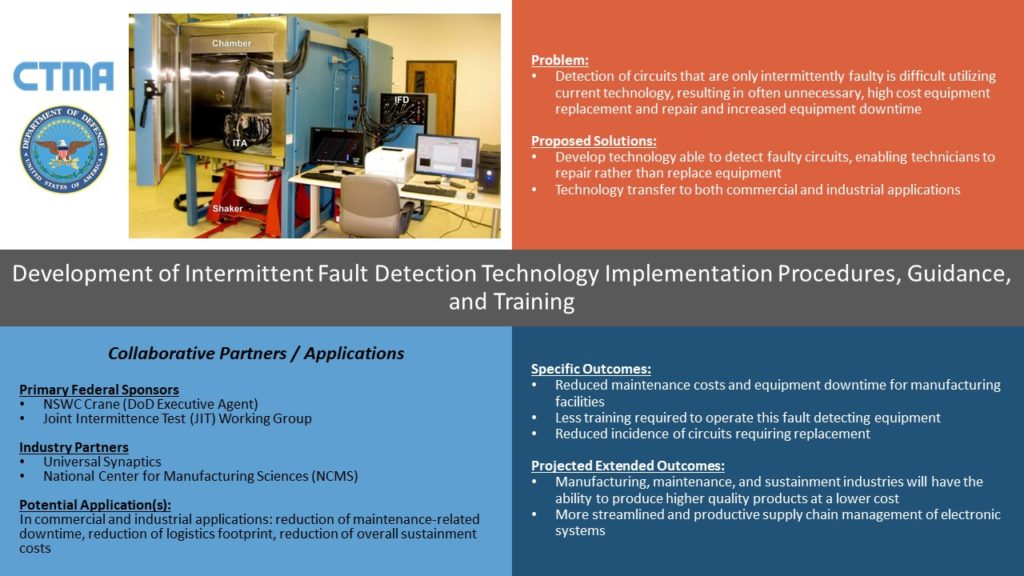

Development of Intermittent Fault Detection Technology Implementation Procedures Guidance and Training

NCMS Project #: 140893

Problem: A potentially faulty electronic system in the field can compromise reliability and safety for the public. Electronic maintenance poses an ever-increasing challenge for the artisan today because of the limitations of current No Found Fault (NFF) equipment and training to the public. The reduced size of electronic chips, coupled with increases in their interactions and complexities of equipment, have led to difficulties in diagnosing system faults; when these faults occur at the component level and are intermittent in nature. Often this very expensive equipment is replaced and not repaired, thus increasing transportation costs for the general public.

Benefit: A device that could locate and accurately diagnose intermittent faults would save millions or even billions of dollars in repair costs, allowing the company to repair the fault rather than replace it, or replace it when deemed necessary. An easy-to-use device would allow maintenance technicians to locate intermittent faults with little training time.

Solution/Approach: The purpose of this collaboration is to build upon the experiences of Fleet Readiness Center South West and Hill Air Force Base in utilizing the Intermittent Fault Detection & Isolation System (IFDIS) and Voyager Intermittent Fault Detector (VIFD) to assess the best strategy to implement this game-changing electronics maintenance capability into NSWC Crane.

Impact on Warfighter:

- Improved readiness

- Increased safety

- Decreased maintenance costs

DOD Participation:

- U.S. Navy (NSWC Crane)

- Joint Intermittence Test (JIT) Working Group

Industry Participation:

- Universal Synaptics

- NCMS

Benefit Area(s):

- Cost savings

- Repair turn-around time

- Maintenance avoidance and reliability

Focus Area:

- Business processes/partnerships