JA MOODY

JA MOODY realizes the longer your ships are docked for repairs, the larger your loss of money/profits. So as a supplier to the marine industry, Moody has long specialized in keeping naval and commercial ships at sea – ensuring your continued delivery of security and goods nationally and around the world.

Exclusive Factory Authorized:

With years of experience, technical expertise, and the precision equipment to do the job right, the industry has taken notice. We earned the honor of being the exclusive authorized repair facility for MORPAC actuators, Nu-Torque Actuators and is an authorized repair facility for Morgan Seattle.

With this kind of recognition and experience, you can rest assured that we will provide a level of service and expertise that you simply won’t find elsewhere. Our highly skilled technicians utilize the latest precision test equipment and tools to guarantee that the problem will be diagnosed and repaired promptly. Our portable test equipment also enables us to provide fast, accurate on-board troubleshooting and repair services at your request.

Vanessa TOTS Valve Hardened Seat – Cold Spray Seat Coating Technology

Problem:

- Seawater remains the most corrosive element in shipboard piping systems, despite advances in valve technology or materials of construction.

- Nickel aluminum bronze & monel materials are the most robust bronze alloy products to resist saltwater corrosion, but long-term exposure eventually leads to failure.

- Corrosion of shipboard piping components and valves due to saltwater leads to high turnover of expensive long lead time valve products, leading to extended yard periods and equipment downtime.

- Erosion effects may show up when passing fluid through small openings, increasing damage to piping components.

Technology Solution:

- Cold spray is an innovative technology for nickel aluminum bronze seating area facing which does not cause thermal alteration to the base as well as to the overlay material.

- Small particles, in solid state, are accelerated to extremely high velocities, (up to 1,200 meter/second or 3,940 foot/second) developing a coating on the relevant base material by an impact process.

- Extend valve life and preserve existing reliable operation with low/zero maintenance needs by improving seat properties specifically for corrosion resistance.

Benefits:

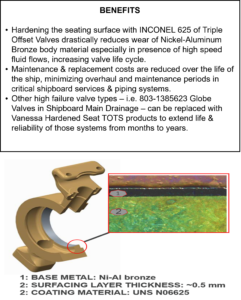

- Hardening the seating surface with INCONEL 625 of Triple Offset Valves drastically reduces wear of nickel aluminum bronze body material especially in presence of high speed fluid flows, increasing valve life cycle.

- Maintenance & replacement costs are reduced over the life of the ship, minimizing overhaul and maintenance periods in critical shipboard services & piping systems.

- Other high failure valve types – i.e. 803-1385623 Globe Valves in shipboard main drainage – can be replaced with Vanessa Hardened Seat TOTS products to extend life & reliability of those systems from months to years.

Graphic: