NCMS Member Perisense Digs Deeper to Illuminate Maintenance Challenges

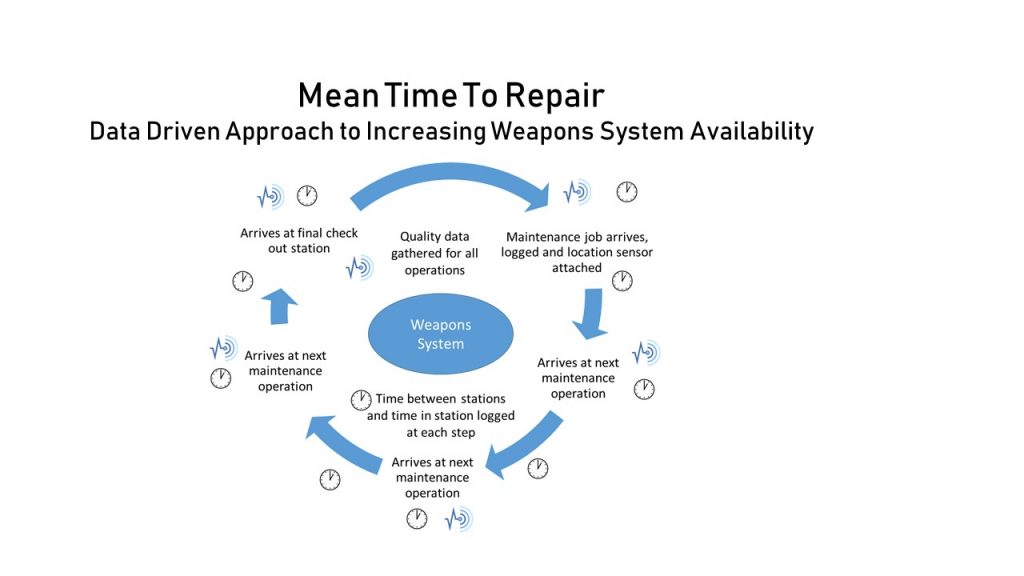

Having skilled maintainers is important to any lifecycle plan. Beyond skill level, having a clear picture of the Mean Time To Repair (MTTR) is a vital aspect of understanding the repair process. How long do tasks take? Where do bottlenecks occur? Having this information radically increases efficiency and productivity when it comes to weapon systems availability.

There is a new approach to MTTR using data captured by sensors and then interpreted to pinpoint such important issues as:

- Identifying bottlenecks in maintenance processes

- Improving inventory management by continuously tracking location and availability of repair parts and various assets (for example forklifts) that are needed intermittently in order to maximize the throughput of repair items

- Supporting preventative maintenance of tools and machines used in repair activities by measuring usage

- Flagging unusual operating conditions in maintenance equipment for performance checks

Funded by the Digital Manufacturing Design and Innovation Institute (DMDII), this project can reveal what changes can be made immediately making positive long-term impacts that result in weapon system availability and warfighter readiness.

“Perisense is working with the Georgia Institute of Technology, which is a perfect fit,” says Dawn White CEO of Perisense. “We offer sensors and right-now data analysis while Georgia Tech supports operational optimization with development implications.”

To learn more about implementing MTTR for increased weapons systems availability contact Dawn White at dwhite@perisense.io.