Focus Area: Coating and Corrosion Prevention

Contact

Jeff Piascik

jpiascik@apsplasma.com

919-931-5622

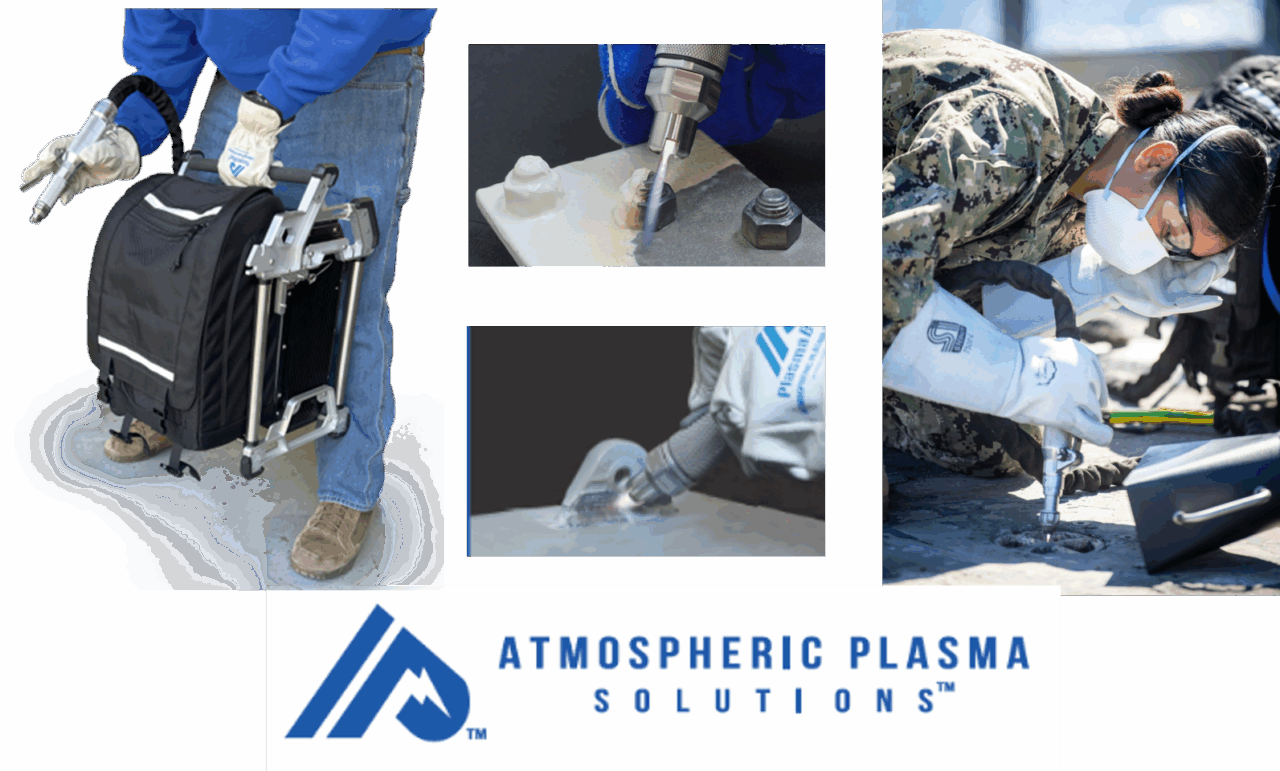

APS provides atmospheric plasma products in manufacturing and maintenance markets with an industry leading combination of power, precision, and portability for surface preparation. APS removes coatings with precision, cleans contaminants with no waste, and prepares the surface for better adhesion while saving time, increasing safety, lowering costs, and eliminating media/solvents.

3-in-1 Surface Preparation System

Problem Statement:

Maintenance and sustainment of DoD combat systems is an annual multi-billion-dollar expense and reduces the readiness rates of critical military combat systems. Removing combat systems for extended periods limits the readiness of all DoD services and compromises the readiness of the warfighter. Combat systems that require precision coating removal around compromised structures require a precision tool that does not impact the structure leading to failure.

Technology Solution Statement:

The 3-in-1 surface preparation technology, PlasmaBlast, delivers an advanced, environmentally responsible solution for precision coating removal, surface cleaning, and adhesion promotion across a wide range of military and industrial platforms. Unlike conventional abrasive blasting or chemical stripping methods, PlasmaBlast operates without expendable media or hazardous chemicals, eliminating over 90% of the de-painting waste stream. This media-free process dramatically reduces environmental impact, simplifies containment and cleanup, and lowers sustainment costs.

PlasmaBlast safely removes partial or complete coating layers while preserving the integrity of the underlying substrate, making it ideal for sensitive, high-value, and mission-critical assets. The system enables effective debris capture during operation, minimizing contamination risks to adjacent systems and work areas.

Designed with operator safety and environmental compliance as priorities, PlasmaBlast presents no undue occupational hazards and meets stringent environmental and safety standards.

Requiring only electricity and compressed air, PlasmaBlast features rapid setup typically less than five minutes, and is lightweight and highly portable. Its modular design supports both depot-level maintenance and forward-operating deployments where mission readiness, speed, and operational flexibility are essential.

PlasmaBlast significantly enhances the Department of Defense’s maintenance and sustainment capabilities by providing a fast, efficient, and safe surface preparation technology that supports increased readiness, reduces downtime, and aligns with the Department’s goals for environmental stewardship, safety, and cost-effective sustainment.

Benefits Statement:

PlasmaBlast offers a versatile, 3-in-1 surface preparation solution that removes coatings, cleans surfaces, and promotes adhesion in a single, streamlined process. Operating without abrasive media or hazardous chemicals, it requires only compressed air and electricity, eliminating the need for consumables and significantly reducing environmental impact.

The system is designed with safety and sustainability in mind—creating no harmful waste streams, minimizing containment and cleanup requirements. Its lightweight, portable design enables a rapid five-minute setup, making it ideal for both shop and field environments, including forward-deployed locations.

PlasmaBlast is fast to train, simple to operate, and requires minimal maintenance, lowering operational complexity and sustainment costs. By eliminating the costs associated with media, hazardous waste disposal, and complex containment, it delivers significant job cost reductions and improves overall maintenance efficiency.

This innovative technology provides a safer, cleaner, and more cost-effective alternative to traditional coating removal and surface preparation methods, helping to improve readiness and reduce downtime across a wide range of platforms and applications.